Wind power

Wind power is one of the world's fastest-growing renewable energy sources

Wind power is one of the world's fastest-growing renewable energy sources

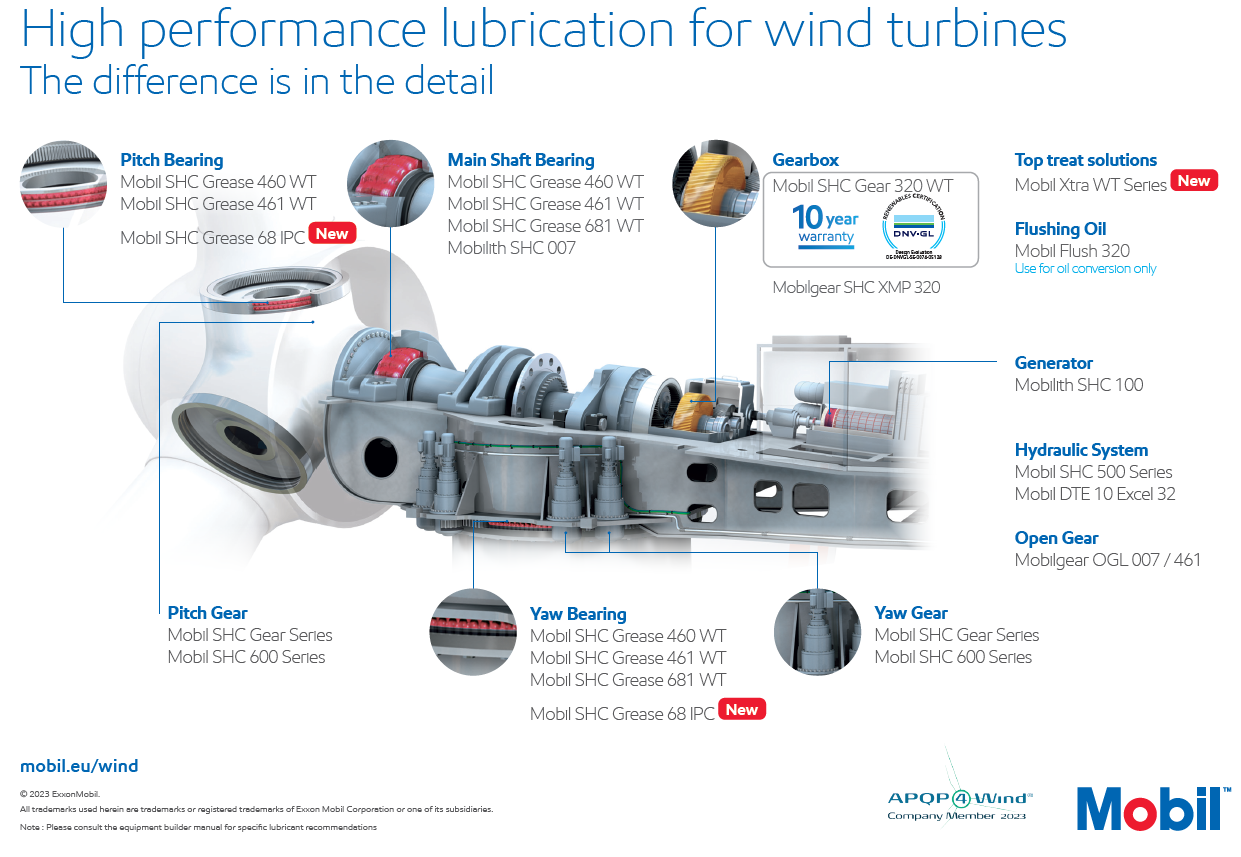

Mobile's products are often approved by major equipment manufacturers. To increase operational longevity and maximize service intervals, synthetic products are advantageously used in combination with Mobile's excellent oil analysis program, MobilServ. Since many wind turbines are located in remote areas, operators prefer long-lasting lubricants to minimize costly and challenging maintenance. Synthetic base materials can help with this. Our range of Mobil™ lubrication solutions is designed to extend the life of the oil and critical components to enhance the availability of wind turbines in both onshore and offshore wind farms.

MOBIL SHC GEAR 320 WT Upgrade to Mobil SHC™ Gear 320 WT - our latest wind turbine gearbox lubricant, formulated in collaboration with leading OEM manufacturers to protect and enhance productivity under extreme conditions, and sold with a 10-year warranty.

An automatic lubricant cartridge entails significant savings in energy costs. Lubricating rotating equipment is considered one of the most critical maintenance tasks. As long as a machine is mechanically sound, it is crucial to supply the correct amount of suitable lubricant at the right time. Wind turbines are considered challenging to reach because they involve many turbines spread over large areas.

Simalube automatic lubricant cartridges significantly reduce maintenance costs and provide the optimal solution to reduce energy costs, thereby supporting the energy transition. Optimal application of the correct amount of lubricant is enabled at the lubrication point, helping to avoid over- or under-lubrication, keeping friction at a low level, reducing energy costs, and extending the lifespan of components.

The automatic lubricant cartridge is available in five different sizes of lubricant dispensers: 15 / 30 / 60 / 125 / 250 ml.

Araldite® 2051 glue allows you to tie up to 40 ° C without being affected by humidity, which allows repair work under cold conditions.

Reduce asset stops by up to 50% with the power to bind in difficult conditions.

Costly, time-consuming maintenance and repair tasks can largely be avoided by using high-quality adhesives, sealants, and lubricants in the manufacturing process of wind turbines. It is essential that you, as a turbine operator or maintenance team, have access to repair solutions that enable quick and easy application, facilitating efficient and smooth maintenance and repairs. Adhesives offer many advantages compared to mechanical bonding techniques due to their versatility in binding and repairing effectively in extremely demanding environments. For bonding added blade elements, we recommend DOWSIL 7091.