Electronics

Discover advanced adhesives and potting compounds for electronics, featuring innovative solutions and proven products.

Discover advanced adhesives and potting compounds for electronics, featuring innovative solutions and proven products.

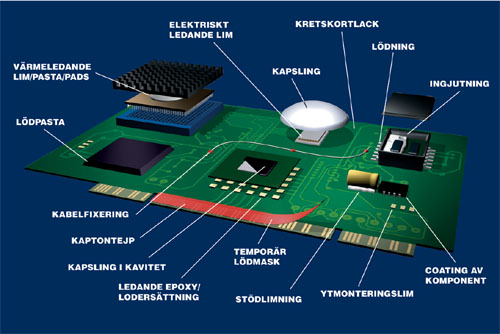

The electronics field is experiencing rapid advancements. The demand for increased performance and efficiency, often combined with the need to reduce product sizes, is driving the development of adhesives and potting compounds.

In our electronics range, you will find the latest developed products for tomorrow's production, as well as well-established products with a strong track record in current electronic components.

Our offerings targeted at the electronics industry are both broad and deep, covering a wide array of areas. The product selection includes various formulations based on silicone, polyurethane, epoxy, MS polymer, cyanoacrylates, and acrylics.

We also offer different types of curing systems, including RTV, heat-curing, 2-component, and UV-curing products.

Here are some of the areas within Electronics where our products can be useful:

Heat transfer

Kapton (polyimide) tape is a type of tape known for its excellent thermal properties. This tape can withstand a wide temperature range, making it suitable for various applications. PPI Kapton tape is extremely durable, chemical-resistant, and provides excellent electrical insulation, making it ideal for use in industries such as aerospace, automotive, and electronics.

We´re here to help!

Contact us for help in choosing suitable products and processes for your specific applications. In our lab, we also have the opportunity to perform small scale tests for adhesion or temperature/humidity ageing.

Selecting the product to use is normally just one step in the process. After that, the product will need to be dispensed in the right place and the in right amount and with a high repeatability.

As part of our work, we are also here to help you with an all inclusive solution, meaning both product selection and process optimisation. We also have opportunities to perform small scale tests (directly on your details) in our lab for robot dispensing and dosing.