Why your silicone is not curing: Inhibition and poisoning of silicones

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Have you ever had trouble getting your 2-component silicone to cure? The silicone could be an adhesive or perhaps an encapsulant for electronics. A silicone system that uses a platinum-based catalyst (a so-called addition curing silicone) are sensitive to certain compounds that prevent curing reactions from taking place. If your silicone is not curing, then you should look for possible inhibitors or poisons that could prevent it.

Let’s start from the beginning. A catalyst is a substance that initiates or increases the speed of a chemical reaction. The catalyst is never removed but continues its purpose over and over until the reaction is complete. In addition curing silicone systems, catalysts based on platinum are often used and it is this particular molecule that is responsible for the curing of the silicone.

In the true meaning of the word “inhibition”, it is a reversible process which delays a reaction. In the case of silicone curing, it makes it more difficult to get a silicone to cure. This can be used on purpose to control when and how fast a certain silicone product cures and to control its pot life (time from mixing of part A and B until the mixture’s viscosity has doubles, i.e. work life). In short, a desired inhibitor is a substance that hinders the catalyst but will release it under the right circumstances, for example a certain time or temperature.

When a substance is preventing the curing reaction from taking place at all or it is taking too long, we are talking about an unwanted inhibitor or even a poison. An unwanted inhibitor, such as sulfoxides, can make the curing more difficult (slower) than anticipated. A poison on the other hand will grab hold of the platinum catalyst and not let go. The poison thereby prevents the curing reaction to proceed permanently.

If your silicone is not curing at all, a poison could be the answer. If your silicone is curing slower than anticipated, it could be an unwanted inhibitor. Regardless, neither is desirable. Let's look at how to avoid them.

If your silicone is not curing, make sure to not have any contact between the uncured silicone and the following substances:

• Tin (Sn): Are present in for example 1-component silicone ahesives (condensation curing) as well as 2-component condensation curing silicones. Also present in some types of PVC plastic.

• Nitrogen coumponds such as amides, amines, nitriles, cyanates etc.

• Sulphur compounds: Present is for example latex, natural rubber, neoprene, PVC, wood, oils and some solvents. Consider the types of protective gloves you are using when working with a platinum-catalyzed silicones and not using a wooden spatula to mix it.

• Some metals such as silver, tin, lead and mercury.

• Some epoxies and polyurethanes.

• Avoid curing your silicone when in contact with poisonous substances. If possible, you’re your silicone in advance or remove the cause of the problem.

• Always clean your surfaces before applying your silicone.

• Use a suitable primer to prevent any effects of inhibition if you can’t remove the source.

• Ensure that any solvents or cleaning agent you use contain low or no levels of sulphur. Alternatively, make sure to wipe off any of its residue before applying your silicone.

• If you are unable to avoid substances that poison your silicone, you can instead limit the contact between them. This could be done by using a primer (see for exemple Nusil MED-163, Nusil MED6-161 and Nusil CF6-135) or by encapsulating these select components with a coating of some sort.

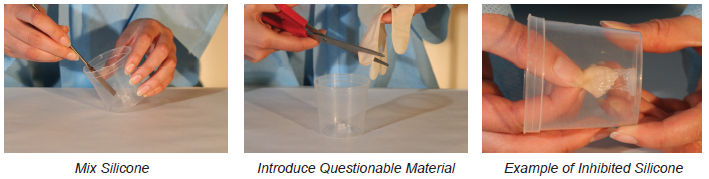

If you are worried that something is poisoning your silicone, but you are not sure what, perform the following test. If for example you are concerned that the plastic gloves you are wearing are having a negative impact on your silicone and contain a poison or inhibitor, cut off a piece of a glove and put it into the silicone as it is curing. You will see clearly if this influences the result.

Removing a cured adhesive can be tricky and the type will determine the method. The main methods are heat, chemicals and mechanical force.

Read more

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more