What is Tg, the glass transition temperature for adhesives?

The glass transition temperature Tg, of an adhesive is usually stated in the techical data sheet. Learn what it means and why you should care.

The glass transition temperature Tg, of an adhesive is usually stated in the techical data sheet. Learn what it means and why you should care.

The glass transition temperature, often shortened to Tg, is a temperature often given for thermoset plastics. When a material, such as an epoxy adhesive, is cured, its chemical structure is permanent. All the polymer chains of the epoxy are cross-linked and have formed a large network. This crosslinking means that the adhesive can neither be melted or dissolved. However, that it cannot be melted does not mean that its mechanical properties stay the same at different temperatures….

What happens is that at a specific temperature, the material softens. The plastic quite suddenly goes from being hard and glassy to a soft and rubber-like. If the temperature then decreases again, the plastic/rubber goes back to its previous state. This is true for all the curing adhesives that are commonly found within adhesive technologies, including epoxies, polyurethanes, silicone, SMP polymers and acrylates.

Silicone is at room temperature already rubber-like! This means that its Tg is somewhere below room temperature. To be more precise, it is usually somewhere around -115 to -40 °C. Epoxies, that tend to be quite hard at room temperature need to warm up to soften sligtly. This means that the Tg is above room temperature – usually somewhere between 30 and 100 °C

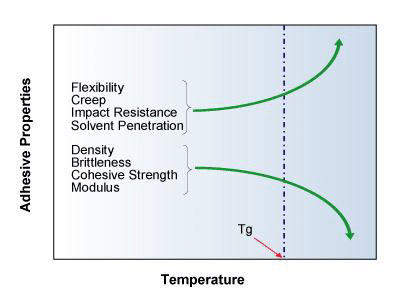

The glass transition temperature for an adhesive is the temperature where the modulus of elasticity (in other words, the flexibility) changes drastically. As the temperature reaches this point, the adhesive goes from being glassy to rubbery. With increased temperature, molecules become increasingly mobile and can move around with much more ease. Below Tg the polymers in the adhesive are ”frozen”, figuratively speaking. Only short segments of the polymers can move and within a very limited space. The low mobility of the polymers means that it cannot adapt as easily to distortion – the material is more brittle and will break instead of flexing.

Another important property that drastically changes at Tg is the coefficient of thermal expansion (CTE). Generally, the CTE is considerably higher above Tg than under.

Properties that change at Tg include flexibility, creep strength, density, hardness, cohesive strength, modulus, chemical resistance and volume.

Absolutely! In many cases, the changes in mechanical properties above Tg are only positive. The adhesive for example becomes more impact and vibration resistant. And as already mentioned: Tg is not a melting point – only a temperature at which some properties change.

Despite what it may sound like, Tg is not an exact point. Depending on the method of measuring Tg, you will get different answers and in addition, interpretation of curves (whether it is done by a person or software) can vary. Comparing values off of technical data sheets can therefore be difficult.

The most common methods for measuring Tg is DCS (Differential Scanning Calirometry), TMA (Thermogravimetric Analysis) and DMA (Dynamic Mechanical Analysis). DSC is considered the most reliable of the methods an also gives an idea of how the properties change above and below Tg. For exemple how elastic the material becomes. To sum up, different methods look at different properties of the material and at what temperature the change takes place:

To give you an example of the difference that can result, let’s look at the 2-component epoxy Epo-Tek 353ND. When Tg is measured using DMA, Tg is 90 °C while using DSC gives us 124 °C – quite a difference!

Why care about the Tg of an adhesive? Well, for someone designing a bond line within a device, it can be of interest to know how this bond (which is essentially like putting a little piece of plastic between your parts) behaves. Since the mechanical properties are different at different temperatures, it can be good to know whether the adhesive will be on the glassy or rubbery side of Tg.

Please keep in mind that the Tg value stated in the technical data sheet for a product represents a certain cure schedule and a 100 % cured material. Generally, heat curing will give a higher Tg and in some cases, epoxies that are cured in room temperature will not get a Tg of over 15 degrees Celsius over the curing temperature, i.e 35 °C if you cure at room temperature!

Removing a cured adhesive can be tricky and the type will determine the method. The main methods are heat, chemicals and mechanical force.

Read more

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more