Stay Safe When Using Industrial UV Lamps – A Safety Guide

Working with a light curing adhesive also means using a UV lamp. UV radiation in high doses is unhealthy. Here is a guide on UV lamp safety.

Working with a light curing adhesive also means using a UV lamp. UV radiation in high doses is unhealthy. Here is a guide on UV lamp safety.

Industrial UV-lamps are used when curing UV-adhesives and coatings. The lamps emit a high intensity of UV light and this light is important to protect yourself from. In this text we go though what you need to think about in regards to UV lamp safety.

UV light is a form of electromagnetic energy. UV light is found just below visible light on the electromagnetic spectrum. Hence, it is something that the human eye cannot see. The human body has a difficult time protecting itself from this type of light, since the natural mechanisms, i.e. shrinking of the pupils, is not triggered in the same way. It is therefore important to use the correct safety equipment when working with UV lamps, and not deactivate the safety mechanisms that the lamp is equipped with.

UV lamps tend to be very bright even to our eyes. But actually, it is not the light that we can see that is the dangerous type, but the light we cannot see.

UV light is normally divided into three categories: UV-A, UV-B and UV-C. All types have the potential to injure an operator if used incorrectly, but UV-C constitutes the biggest risk and can, among other things, burn your corneas. UV-B is the type of radiation that can cause sunburn. Luckily, neither UV-C or UV-B is used in industrial UV lamps, but rather UV-A, that is slightly better comparatively.

UV light is the biggest cause of melanoma and can damage the cornea of the eye.

Electromagnetic spectrum (not to scale)

Most industrial UV lamps are designed with safety functions. Some examples are shielding, safety latches, intuitive design and light absorbing plastics that prevent the light from ever reaching an operator. Additional materials, such as safery shields, can also be purchased. In the cases where this protection is not sufficient, it is important that the operator in question has received a satisfactory training in how to protect themselves from exposure to minimize any safety risks.

A radiometer is a small device that can measur e the intensity of UV light in a certain location. Apart from the fact that it is always a good idea to keep track of the efficacy of the lamp, it can also be used to measure the exposure of an operator when working with the UV-lamp. Turn on the lamp and hold the sensor of the radiometer approximately where the operator’s exposed skin would be present during use. Compare this to what you would be exposed to during a normal day in the sun. Hopefully, you will see that the UV lamp is considerably lower than this. Remember to make sure that your radiometer matches the wavelengths emitted by your lamp.

e the intensity of UV light in a certain location. Apart from the fact that it is always a good idea to keep track of the efficacy of the lamp, it can also be used to measure the exposure of an operator when working with the UV-lamp. Turn on the lamp and hold the sensor of the radiometer approximately where the operator’s exposed skin would be present during use. Compare this to what you would be exposed to during a normal day in the sun. Hopefully, you will see that the UV lamp is considerably lower than this. Remember to make sure that your radiometer matches the wavelengths emitted by your lamp.

The sun will emit a UV-A intensity of approximately 2-5 mW/cm2 on a sunny day here on earth.

Contact us for help!

Removing a cured adhesive can be tricky and the type will determine the method. The main methods are heat, chemicals and mechanical force.

Read more

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

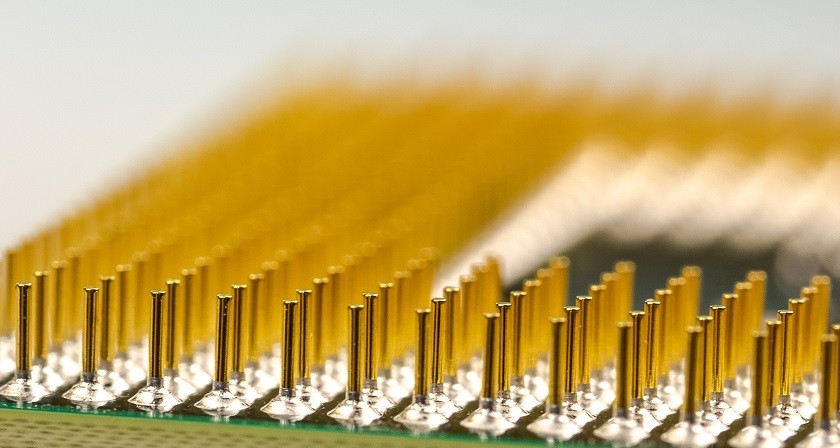

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more