Plasma treatment for better adhesive bonding

Plasma treatment is an effective method for surfaces prior to adhesive bonding allowing better wetting and higher adhesion stronger bonds.

Plasma treatment is an effective method for surfaces prior to adhesive bonding allowing better wetting and higher adhesion stronger bonds.

Plasma treatment is an effective and versatile method to pre-treat surfaces prior to adhesive bonding. It allows better wetting and higher adhesion, resulting in stronger bonds.

In school, we are taught that there are three material states: solids, fluids and gases. But there are actually four! The fourth state is plasma, which is also the most common material in the universe.

Plasma is a collection of atoms that have absorbed enough energy in order to separate their electrons from their nucleus. These electrically charged particles are called ions. Plasma is a mixture of ions, radicals, electrons and neutrons.

When this happens, the plasma no longer functions as a gas. This mixture of electrically charged particles now has electrical properties and creates a magnetic field. The patricles also give off light and other forms of electromagnetic radiation.

Gases can turn into plasma with several methods. All of them come down to adding energy to a gas. A spark in a gas will create a plasma that is useful in industrial processes when for example cleaning surfaces. Plasma burners are also used to cut metals.

The sun is the largest plasma (closest to earth). The sun’s enormous heat rips away electrons from hydrogen gas and helium to create plasma. In essence, the sun is a giant ball of plasma.

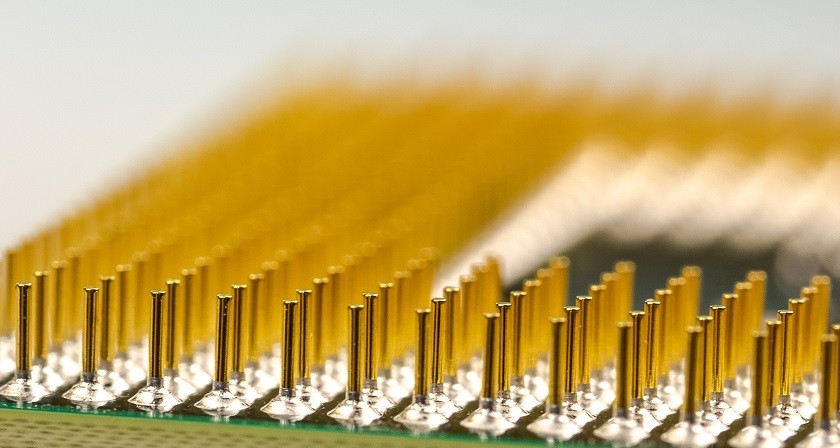

Plasma technology is used within many indutries where bonding of different materials, change their surfaces or increase wetting (decrease the contact angle) and get better adhesion.

With plasma treatment, almost all surfaces can be modified in one way or another. It could be cleaning, activating, etching and/or coating with hydrophobic or hydrophilic layers, barriers or friction reducing surface treatments,

Within adhesive bonding, plasma is mainly used for cleaning of surfaces (all materials) and chemical as well as physical modification of the surfaces of hard-to-bond plastics. With this type of pre-treatment, a better wetting of the surface is achieved, resulting in better adhesion, even for difficult plastics such as polyethylene, polypropylene or Teflon.

Comparison of shear strength measured on overlap bonds with a 2-component epoxy adhesive with and without plasma pre-treatment.

| Material | Untreated | Treated |

| Polyamide (PA) | 6,1 | 28,5 |

| Polyethylene (PE) | 2,7 | 22,5 |

| Polyethylene theraphtalate (PET) | 3,8 | 12,0 |

| Polypropylene (PP) | 2,7 | 22,2 |

| Polystyrene (PS) | 4,1 | 28,9 |

| Teflon (PTFE) | 0,5 | 5,4 |

| Polyvinyl fluoride (PF) | 2,0 | 9,2 |

Plasma treatment is said to have three main effects:

The gas supplied to the plasma chamber, often oxygen gas, turns into plasma. The plasma reacts with organic compounds on the surface and combusts them. Any bi products created will be sucked away thanks to vacuum or low pressure. Metal oxides are aso reduced.

When using oxygen gas, water vapour or air is used as carrier gas, polar groups can be chemically attached to the plastic surface being treated. These polar groups improve wetting and thereby adhesion. This effect only lasts a certain amount of time, and the time can vary depending on the type of plastic.

When the plasma is launched at the surface, a relatively controlled surface structure is created. This effect is permanent and can be both chemical and physical.

Using specific gases, the surface can be functionalized with side groups to obtain different properties. This method is used to for example create a hydrophobic surface.

There are different types of plasma equipment. The choice depends on both practicality and what the purpose of using the plasma is.

Low pressure plasma uses a chamber with vacuum (or very low pressure). A small amount of gas is activated using radio frequency, creating ions, electrons and other reactive patricles that make up the actual plasma.

Low pressure plasmas have the following three effects:

By adjusting process parameters such as pressure, effect, time, gas flow and type of gas, the operating properties of the plasma is determined. Multiple effects can be achieved in one process step.

The most common carrier gases to use are oxygen, water vapour and argon gas.

Diener Femto, Pico and Nano

Atmospheric plasma technology does not use a chamber. Instead, a gas (air) flows through a high voltage nozzle to create the plasma which flows out over the surface where its pointed. Everything happens at atmospheric pressure.

Two main effects occur during atmospheric plasma treatment:

In addition, any loose particles on the surface are removed by the compressed air used to created the gas beam.

Varying process parameters, such as time and distance, different effects can be attained. Some heat is produced during treatment.

Diener Plasma Beam

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more