Low temperature and cryogenic adhesives

Sometimes an application requires a cryogenic adhesive to remain flexible or just avoid becoming fragile and crack at very low temperatures.

Sometimes an application requires a cryogenic adhesive to remain flexible or just avoid becoming fragile and crack at very low temperatures.

In certain industries and applications, it is common for an adhesive joint to have to withstand extreme temperatures – both high and low. In this post, we will focus on low temperatures.

Unlike at high temperatures, an adhesive does not deteriorate (break down chemically) at low temperatures, or even at cryogenic temperatures. Even so, the properties of the adhesive can change dramatically.

The main problem at low temperatures is that the modulus of the adhesive increases. In other words, the adhesive becomes less flexible the lower the temperature. When the adhesive is less flexible it is also automatically more brittle and more sensitive to for example impact and vibrations. The worst case scenario is that the adhesive cracks.

Other negative effects of low temperatures could be that the the adhesion between adhesive and substrate is lowered. De-bonding can even occur.

Temperatures in the range of a normal winter day is usually no problem to most adhesives, depending on what the joint will be subjected to in addition to the cold.

Since it is above all the modulus that is affected, the adhesive types that exhibit the best results at low temperatures are those with an already low modulus or high flexibility. In many applications, it is important that an adhesive bond remains flexible and that the strength / adhesion is kempt high.

Using a flexible adhesive can also have advantages when the bonded details will be subjected to temperature changes where the thermal expansion differs between two substrates.

Epoxy and silicone are the two types of adhesives that cope best with extremely low or cryogenic temperatures. Often, adhesives that are high temperature resistant also do well at low temperatures.

Standard silicone grades tend to be able to retain their flexibility down to about -60 ˚C. There are specially formulated silicones that can manage the same even below -100 ˚C.

Epoxy based adhesives are certainly not as flexible as silicones. However, they tend to be both high and low temperature resistant and there are cryogenic adhesives proven to work well in those types of environments as well.

Don’t get too hung up on the recommended temperature values stated in the technical data sheet (TDS) of an adhesive. As an example, for Epo-Tek, the minimum operation temperature is specified as -55 ˚C. This is not because something in particular happens at this temperature, but because tests have only been performed down to -55 ˚C.

Many epoxy adhesives can manage much lower temperatures without losing too much adhesion or strength. In fact, there have been some great results even at cryogenic temperatures between -150 ˚C and -273 ˚C (absolute zero). Certain products have even been shown to become stronger at lower temperatures.

As always, you always want to consider that the temperature resistance of an adhesive is not only affected by the temperature itself. Other factors such as exposure time, temperature variations, atmosphere, joint design and mechanical stress also weigh in. In addition, the properties of the cured adhesive can change in certain ways, especially near the limits stated. It is therefore important to verify the temperature resistance for the specific application in question.

Aerospace, space, refrigerator and freezer equipment, SEM (Scanning Electron Microscope) can require adhesives that function at low or cryogenic temperatures. It can be anything from potting or encapsulation of electronic components, coatings or adhesion of components.

General limits for standard grade adhesives:

Silicone: Standard grades normally between -40 and -60 ˚C.

SMP polymers: Normally -40 ˚C.

Epoxy: Standard grades normally -55 ˚C.

Polyurethane: Normally -40 ˚C.

Akrylic: Normally -40 ˚C

Cyanoacrylate: Normally -55 ˚C

Anaerobic: Normally -55 ˚C

Examples of some products developed for extremely low or cryogenic adhesive temperatures are listed below.

Nusil R3-2160: 2-component adhesive / sealant, silicone elastomer. Has performed well in applications down to -140 ˚C.

Nusil R-2655, Nusil R-2560: 2-component silicone for potting, encapsulation or coating. Maintains its properties down to -115 ˚C.

Nusil R-2949: Thermally conductive 2-component adhesive. Maintains its properties down to -115 ˚C.

Nusil R-2634: Electrically conductive silicone adhesive. Has performed well in applications down to -140 ˚C. Has performed well in applications down to -140 ˚C.

Nusil CV7-1142-1, Nusil CV-2510: Low outgassing silicones for space applications. Can be used as adhesives, sealants, encapsulation. Recommended use down to -115 ˚C.

Nusil CV-1144-0: Silicone based low outgassing coating (atomic oxygen) that maintains its properties down to -115 ˚C.

Epo-Tek 301-2: Epoxy adhesive with low viscosity and high shear strength at cryogenic temperatures. Low outgassing.

Epo-Tek T7110: Thermally conductive epoxy adhesive with high shear strength at cryogenic temperatures.

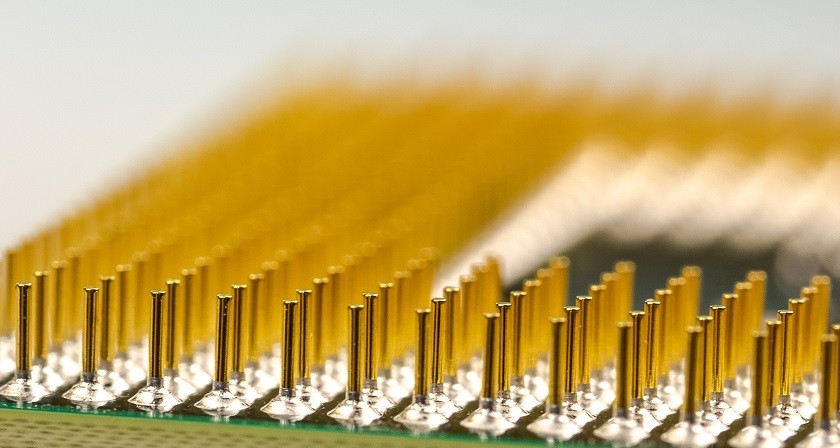

Epo-Tek H20E: Electrically conductive epoxy adhesive. Low outgassing.

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more