How to choose a biocompatible silicone adhesive

We guide you in how to choose the right biocompatible silicone adhesive for your application and manufacturing process.

We guide you in how to choose the right biocompatible silicone adhesive for your application and manufacturing process.

Choosing the right biocompatible silicone adhesive does not only give you the best end result, but can also improve your process efficacy. The adhesive youls fit the needs of your process. Let’s take a look at what to consider.

Will the adhesive be implanted? If so, for how long? A biocompatible silicone adhesive can have various levels of tested biocompatiblity.

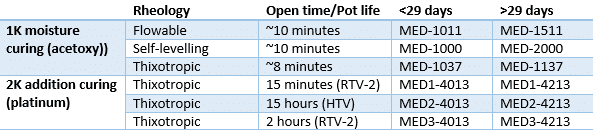

Most medical applications require materials to be tested according to ISO 10993. This standard does, however, have different types of tests that can be used. Biocompatible silicone adhesives with ISO 10993 can be approved for long-term implantation (>29 days) or short-term implantation (<29 days).

Silicone adhesives can bond many types of substrates used within the medical industry. Silicone adhesives are perfect for bonding other silicone details, as well as metals and plastics. Certain substrates may require pre-treatment. In these cases, a primer, plasma treatment or Corona can be used to improve adhesion, bond strength and long-term durability.

A factor to also take into consideration is inhibition. Addition curing silicones (2-component) can in contact with certain substances be prevented from curing properly. This should be avoided – especially in a medical application. Hence, consider which solvent, chemicals or substrates that the adhesive can come in contact with before curing. You can read more about inhibition and poisoning of silicones HERE.

The biocompatible silicone adhesive must of course also be functional in the bonding process. As a start, as yourself the following questions:

A 1-component adhesive is often easier to handle as a 2-component adhesive must be mixed (often by using a dispensing gun and static mixer). On the other hand, a 2-component adhesive’s cure speed can be more easily managed which leads us to the next question.

A 1-component silicone adhesive is moisture curing which means curing takes place when it is in contact with the surrounding air. This means that they only real way to control the cure speed is to control the relative humidity of the air. The 1-component silicone first forms a skin on the surface closest to the air and then wanders inwards. At normal humidity levels, the cure speed is around 2 mm depth per 24 hours. Moisture curing silicones should not be exposed to over 60 ˚C before it is fully cured. Confined silicone material or too deep sections may cure very slowly or not at all.

The cure schedule of a 2-component silicone adhesive is more adjustable since it is mainly influenced by the temperature. At room temperature, full curing is usually achieved within 24 hours and a common cure schedule is 15 minutes at 150 ˚C in an oven.

1-component adhesives have an open time of around 10 minutes which is the time it takes for a skin to form. Different product formulations give widely different pot lives for 2-component adhesives – anything from a few minutes to several days. In the latter case, heat curing will be a requirement (HTV).

The most time efficient combination of cure properties are given with heat curing in an oven. It is then possible to choose an adhesive with a long pot life (minimizing the need for static mixer changes etc.) while at the same time getting a fast cure speed. Consider, however, that your substrates must also withstand these temperatures (usually a minimum of 100 ˚C) and that some investments (ovens) will need to be made.

Fot the sake of dispensing and application, it is also important to consider other factors, such as the reology of the biocompatible silicone adhesive.

Below is a selector guide of the most common biocompatible silicone adhesives from Nusil.

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more