Repacking of glue into syringes

Sometimes the glue you have chosen may need to be repackaged into a package that suits your gluing process better, often smaller syringes. Get tips here!

Sometimes the glue you have chosen may need to be repackaged into a package that suits your gluing process better, often smaller syringes. Get tips here!

Sometimes when you have to glue smaller details or perhaps when you want to use a dosing device or a table robot, the original packaging of an adhesive does not always work so well. On such occasions, it may be a good idea to repackage the glue into smaller syringes. Here we will go through how to repackage glue for syringes in a simple and safe way!

In the video below, we show you how you can easily repackage glue such as silicone or MS polymer into smaller syringes.

Viscous glue in cartridge

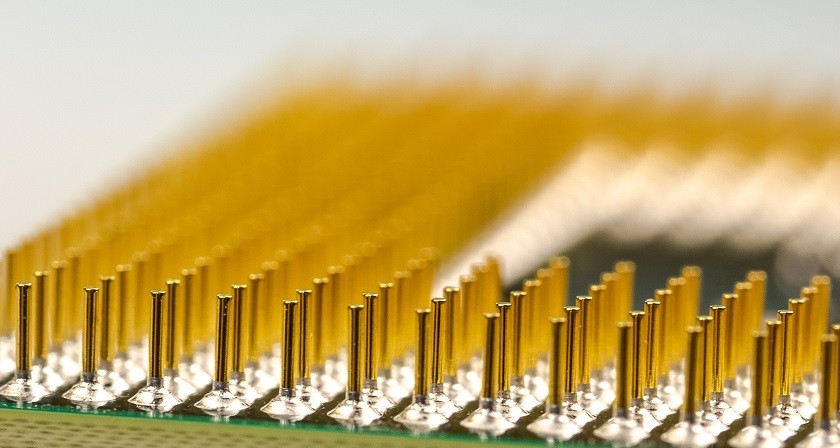

Many 1-component products such as silicone glue or MS polymers are sold in cartridges between 290 and 330 ml. These are dispensed with a skeleton gun (alternatively lift pressure driven or battery powered glue gun). Many of these types of glue are viscous.

When repacking glue into syringes, the glue can be transferred to the empty syringe without a plunger and without a cap. With this method, the air is pushed out of the syringe while you fill it. Then the piston is inserted - still without a cap - to be able to push out all the air. Stop when the glue has reached the tip of the syringe and then close the syringe by putting on the cork (also called the stopper).

Repacking of viscous glue for syringes.

Order:

1. Glue

2. Piston

3. Sealer

Viscous glue in tube

Another common packaging type for, for example, silicones and MS polymers is the 90 ml tube. These types of tubes are flexible as they are in many cases, but it can still be difficult to achieve an even and fine dosage with them due to the fact that they can only be handled manually. To repack a viscous material from a tube to a syringe, do exactly the same as with a cartridge. One tip is to use a so-called key to get as much as possible out of the tube.

Light-flowing glue

For a light-flowing glue, the methods above will not work as well, but with a high risk of smearing. To prevent the glue from flowing out of the tip, put the cap on beforehand. Then pour in the glue (which can come from any type of packaging). But remember to make sure to leave room for the plunger.

Now it's tricky to get in the piston. A tip is to angle it a little and almost bend one edge in to release as much air as possible.

Order:

1. Sealer

2. Glue

3. Piston

In case of air bubbles in the syringe

It easily happened that there will be some air bubbles in the syringe after all. If air bubbles have now appeared, you can centrifuge the syringes with the tip upwards. Then, after the spin, the air will have settled towards the top and you can easily push it out.

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more