Adhesive viscosity: what you need to know

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Viscosity is a concept which describes how a liquid material flows. Adhesive viscosity is an important factor to consider when setting up your bonding process, regardless of whether it’s manual in a small scale or an automatic high-speed production.

If something has a low viscosity, it flows easily, and if something has a high viscosity, it flows with more difficulty – it is a viscous fluid.

Values of so called dynamic viscosity (which is the type normally used within the adhesives industry) is usually stated in the technical data sheet (TDS) of the adhesive. The unit can be centiPoise (cP or cPs) or mPa·s where 1 cP = 1 mPa·s.

Regarding thicker adhesives,such as certain silicones or SMP-polymers, they can be difficult to measure using dynamic viscosity testing. Another type of measurement for flow can be used instead, extrusion rate. This value is usually listed in units such as g/min or ml/s. What is measured is the amount of material extruded from a certain apparatus during a specific time and pressure.

Apart from viscosity values, you will often also find a mention of the consistency of of the adhesive in its specification. Some terms commonly used are flowing/free-flowing, paste/non-flowing and thixotropic.

Please note that it can be quite difficult to compare viscosities of different adhesives due to the fact that any values will depend on the method or standard used when measuring, such as the rpm. The viscosity is also dependent on outer factors including temperature.

When choosing an adhesive, it is important to consider that the adhesive itself as well as its viscosity is suitable for both the final product and the gluing process.

Some examples of questions to ask yourself:

A fluid is thixotropic when its viscosity is affected by movement (shear stress) and also is dependent of the time during which this movement takes place. In reality, this means that the viscosity is lowered more when the fluid is stirred for longer.

It also means that an adhesive that is thixotropic will not flow. Instead, it will maintain the shape it had when you dispensed it.

When the adhesive is not exposed to shear stress, it will stop flowing. But as you stir it, or dispense it for that matter, it will start to get more thin until you stop (with a delay). Ketchup is an example of a thixotropic fluid. A thixotropic adhesive does not really tell you anything about the adhesive viscosity. A fluid can be thixotropic and still have a low viscosity, as viscosity is measured under shear stress.

A thixotropic adhesive is favorable to choose when assembly is to be performed vertically or when it is important that adhesive material does not flow where it is not supposed to.

A non-thixotropic adhesive can sometimes also be made into a thixotropic one by adding a special kind of filler. This way you can get the same chemical and adhesive properties but with a different type of flow. Compare for example Epo-Tek OG198-54 and Epo-Tek OG198-55

When choosing an adhesive for your application, it is advantageous if you consider the adhesive viscosity to best suit your application and process.

Read more

Medical grade adhesives are commonly biocompatibility tested according to ISO 10993 standard. Choose Epoxy, UV-curing adhesive or silicone.

Read more

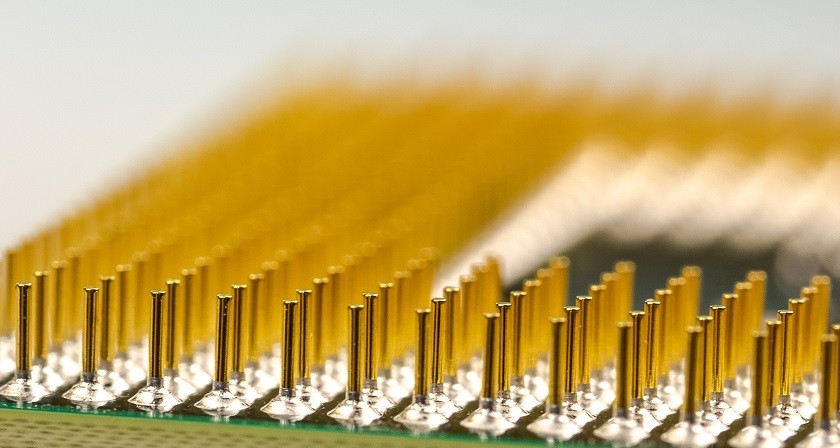

Electrically conductive adhesives are used in many different types of industries and applications. Some examples are electronics, solar cell, medical, aerospace, space and automotive applications.

Read more

Silicone rubber is one of the most difficult-to-bond rubbers. We will give you options for adhesives that can help you bond silicone.

Read more

Your silicone is not curing even though you have followed every instruction? Inhibition could be the reason.

Read more